As we step deeper into the age of technology, artificial intelligence (AI) is increasingly finding its way into industries that demand precision, efficiency, and innovative solutions. One such emerging trend is the development of AI generated 3D model compliant mechanisms. These innovative devices are changing the way engineers approach the design and manufacturing of systems that require movement and force transmission.

In this article, we’ll explore the fascinating world of AI generated 3D Model compliant mechanisms, their impact on engineering, the benefits they offer, the challenges ahead, and how industries such as robotics, medical devices, aerospace, and consumer electronics are adopting them.

What Are Compliant Mechanisms?

To understand the significance of AI generated 3D model compliant mechanisms, it’s essential to start with the basics. A compliant mechanism is a device that transfers or transforms motion, force, or energy through the elastic deformation of its flexible components, rather than through rigid body motion and traditional joints like hinges and bearings. These mechanisms rely on the material’s inherent flexibility, bending, and stretching to achieve the desired motion.

For example, the common spring is a basic compliant mechanism. It stores energy when compressed or stretched and releases it when returned to its original shape. Similarly, more complex compliant mechanisms can be designed to execute intricate movements without relying on multiple parts and moving joints.

The Role of AI in Compliant Mechanism Design

In traditional mechanical design, engineers typically rely on well-known principles, formulas, and trial-and-error methods to design compliant mechanisms. However, the rise of AI generated 3D model compliant mechanisms has revolutionized this process. AI, powered by machine learning algorithms and generative design, can explore countless design possibilities, evaluate each, and produce optimized models that far exceed the limitations of traditional design processes.

How Does AI Generate Compliant Mechanisms?

Generative Design with AI

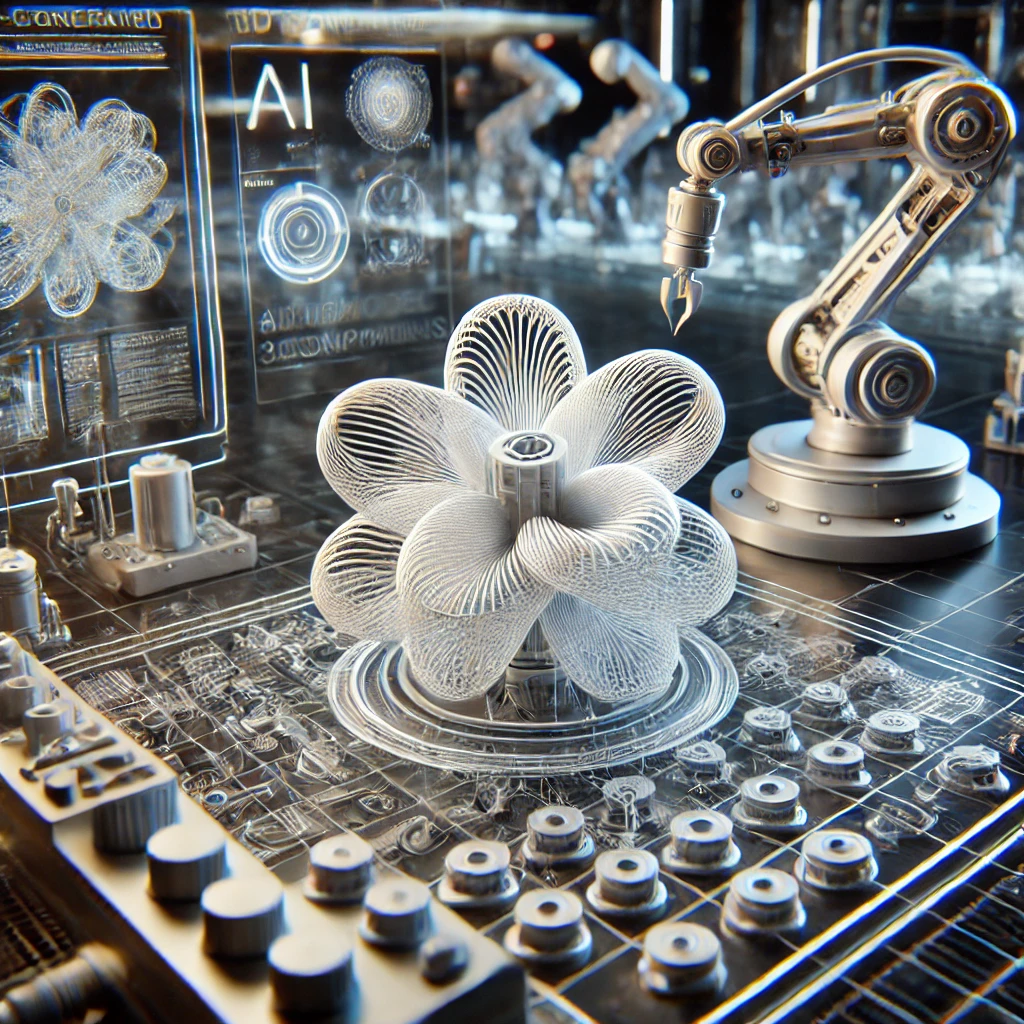

Generative design is a process where engineers input specific design parameters, such as load requirements, material constraints, and desired functions, into AI software. The AI algorithm then explores thousands of design iterations, refining and improving with each step. When applied to compliant mechanisms, AI algorithms search for the most efficient design that balances flexibility, strength, and performance.

This process is fundamentally different from traditional design methods. Instead of manually calculating every aspect of a compliant mechanism, the AI software generates, tests, and evaluates designs, producing models that are optimized for performance, cost, and manufacturability. This dramatically reduces the design cycle and allows for innovation at a speed that would be impossible to achieve manually.

Finite Element Analysis (FEA) and Simulation

After generating a compliant mechanism design, AI-driven tools use finite element analysis (FEA) and simulations to predict how the design will behave in real-world conditions. These simulations assess the stress, strain, and deformation of the mechanism under different loads and movements. This allows engineers to ensure that the mechanism will meet performance requirements and avoid structural failure.

Integration with 3D Printing (Additive Manufacturing)

Once an AI generated 3D model compliant mechanisms has been designed and optimized, it can be manufactured using 3D printing. Additive manufacturing allows for the precise fabrication of complex geometries that would be impossible or extremely costly to produce using traditional methods. By combining AI generated designs with 3D printing, engineers can create highly intricate, efficient, and cost-effective compliant mechanisms.

Advantages of AI Generated 3D Model Compliant Mechanisms

1. Design Optimization and Innovation

Traditional compliant mechanisms rely on known designs and engineering principles. AI, on the other hand, explores uncharted territory, resulting in innovative designs that might not have been considered by human engineers. AI generated 3D model compliant mechanisms are often more efficient, reliable, and adaptable to specific applications.

By analyzing thousands of possibilities, AI can create mechanisms with fewer parts, reduced friction, and enhanced performance. It’s no longer necessary to manually optimize every joint or connection AI does the heavy lifting by proposing designs that maximize flexibility while minimizing the number of components.

2. Cost and Time Efficiency

AI dramatically shortens the design cycle for compliant mechanisms. Instead of spending weeks or months manually designing, testing, and iterating on a model, AI can generate and optimize a design in a matter of hours. This not only saves time but also reduces the associated labor costs.

Moreover, AI can optimize designs for material efficiency, reducing waste in the production process. Compliant mechanisms often require fewer parts than traditional mechanisms, which further lowers production costs and assembly times.

3. Customization for Specific Applications

One of the most exciting aspects of AI generated 3D model compliant mechanisms is the ability to tailor them for specific applications. AI can design compliant mechanisms that meet precise requirements, such as specific load-bearing capacities, movement constraints, or material properties. This level of customization is invaluable in industries like robotics, medical devices, automotive, and aerospace, where unique, high-performance solutions are required.

4. Improved Durability and Reliability

Because AI generated 3D model compliant mechanisms eliminate many of the traditional joints, hinges, and moving parts found in mechanical systems, they are often more durable. The absence of these components reduces the risk of wear and tear, leading to longer-lasting mechanisms that require less maintenance.

The elasticity of compliant mechanisms allows them to withstand repeated stress without experiencing the same levels of fatigue as traditional systems. AI can also predict how these mechanisms will behave over time, ensuring that they maintain performance even after extended use.

5. Simplification of Manufacturing Process

The integration of AI generated compliant mechanisms with 3D printing simplifies the manufacturing process. Traditional manufacturing methods, like casting, milling, and assembling, often require complex tooling and multiple steps. By contrast, 3D printing can fabricate an entire mechanism in a single step, often in one piece. This reduces manufacturing complexity, shortens lead times, and lowers costs.

Applications of AI Generated 3D Model Compliant Mechanisms

The integration of AI in the design of compliant mechanisms is already making waves in several key industries, each benefiting from the unique advantages AI generated designs offer.

1. Robotics

Robotics is one of the most prominent fields where AI generated 3D Model compliant mechanisms are being used. Flexible joints and actuators designed using AI can improve a robot’s ability to perform delicate tasks, such as handling fragile materials or interacting with humans. These mechanisms allow robots to exhibit greater dexterity, speed, and precision while maintaining lightweight and energy-efficient designs.

For example, in soft robotics, compliant mechanisms designed by AI are helping create robots that can navigate and manipulate environments in ways that were previously impossible. These robots are particularly useful in fields like medicine, agriculture, and logistics, where gentle interaction with objects is crucial.

2. Medical Devices

Medical devices often require high precision, miniaturization, and patient-specific customization. AI generated 3D model compliant mechanisms allow for the design of minimally invasive surgical tools, prosthetics, and other medical devices that are lightweight, flexible, and adaptable.

One significant advantage is the ability to tailor devices to a patient’s anatomy. AI can analyze a patient’s unique characteristics and create a customized medical device that perfectly fits their needs, improving outcomes and reducing complications.

3. Aerospace and Automotive Industries

In aerospace and automotive engineering, weight and performance are critical. AI generated 3D model compliant mechanisms are playing an essential role in reducing the overall weight of vehicles and aircraft by minimizing the number of components and optimizing the use of materials.

For example, AI generated mechanisms can help design lightweight, flexible control surfaces or energy-absorbing structures for aircraft and spacecraft. These designs can improve fuel efficiency and performance, all while maintaining safety and reliability.

Similarly, in the automotive industry, AI generated 3D model compliant mechanisms are helping engineers design more efficient suspension systems, lightweight structural components, and energy-efficient actuators that enhance the performance of vehicles while reducing their environmental impact.

4. Consumer Electronics

The demand for miniaturization and enhanced performance in consumer electronics makes AI generated 3D model compliant mechanisms particularly valuable. From hinges for folding smartphones to flexible connectors for wearable technology, compliant mechanisms designed by AI can improve product reliability, durability, and user experience.

For instance, manufacturers can use AI to design better hinges for foldable smartphones, where durability and precision are crucial for the repeated opening and closing of the device.

Challenges and Limitations of AI Generated Compliant Mechanisms

Despite the numerous benefits, there are still challenges to overcome when implementing AI generated 3D model compliant mechanisms:

1. Material Limitations

While AI can generate incredibly optimized designs, the performance of these mechanisms is ultimately limited by the available materials. Current 3D printing materials may not always offer the ideal combination of flexibility, strength, and durability required for specific applications. However, ongoing advancements in materials science are expected to close this gap, leading to new possibilities for compliant mechanisms.

2. Computational Demands

The generative design process requires significant computational resources, especially when designing complex mechanisms for demanding applications. Although cloud computing and advances in AI algorithms are helping mitigate this issue, the high computational cost can still be a barrier for smaller companies or individual engineers.

3. Manufacturing Precision

While 3D printing has advanced significantly, ensuring that AI generated designs are manufactured with the required precision remains a challenge. High-performance applications, such as aerospace or medical devices, require incredibly tight tolerances, and even small deviations can lead to failure.

[sp_easyaccordion id=”4262″]

The Future of AI Generated 3D Model Compliant Mechanisms

The future of AI generated 3D model compliant mechanisms is set to revolutionize industries by offering more efficient, customized, and cost-effective solutions for a wide range of applications. As AI technology continues to evolve, it will enable more advanced designs, materials, and manufacturing techniques, further enhancing the potential of these mechanisms.

From robotics and medical devices to aerospace and consumer electronics, the possibilities are endless. However, challenges remain in terms of computational demands, material innovation, and manufacturing precision. Nonetheless, with continued advancements, AI generated 3D model compliant mechanisms will increasingly be at the forefront of engineering design, creating systems that are more flexible, efficient, and sustainable.

By embracing the future of AI in the design and manufacturing of compliant mechanisms, industries can unlock new levels of performance and innovation, making it an exciting time for engineers, manufacturers, and innovators alike.

Check More

- What is the opposite of Artificial Intelligence?

- AI Half Burned Face: A New Era in Digital Art

- How Artificial Intelligence is Shaping the Future of Teaching and Learning in 2024

- How Kialo Uses Artificial Intelligence to Enhance Online Debates